工业涂装流水线定制化服务:从需求到落地的全流程解析

在制造业转型升级的背景下,工业涂装流水线制作商正从标准化设备供应商向“一站式解决方案服务商”转型。其核心价值在于深度理解客户需求,通过模块化设计与柔性化生产,打造与生产工艺高度契合的涂装系统。以下从需求分析、方案设计、实施落地三个阶段,解析定制化服务的全流程。

Against the backdrop of manufacturing transformation and upgrading, industrial coating assembly line manufacturers are transforming from standardized equipment suppliers to "one-stop solution service providers". Its core value lies in a deep understanding of customer needs, creating a coating system that is highly compatible with production processes through modular design and flexible production. Below, we will analyze the entire process of customized services from three stages: requirement analysis, solution design, and implementation.

一、需求洞察:从工艺痛点到场景适配

1、 Requirement Insight: From Process Pain Points to Scene Adaptation

定制化服务的起点是精准捕捉客户需求。制作商首先会组建跨领域团队,包含涂装工艺工程师、设备设计师及生产管理顾问,通过实地勘测与多轮沟通,梳理客户的核心痛点。例如,某汽车零部件企业面临多品种、小批量涂装需求,传统流水线换型耗时长达4小时,严重影响交付效率。制作商通过分析产品尺寸、材质及工艺参数,提出“快速换色系统+智能分拣模块”的解决方案,将换型时间压缩至30分钟内。

The starting point of customized services is to accurately capture customer needs. Manufacturers will first form cross disciplinary teams, including coating process engineers, equipment designers, and production management consultants. Through on-site surveys and multiple rounds of communication, they will identify the core pain points of customers. For example, a certain automotive parts company is facing the demand for multi variety and small batch painting, and traditional assembly line changeover takes up to 4 hours, seriously affecting delivery efficiency. The manufacturer proposed a solution of "fast color changing system+intelligent sorting module" by analyzing product size, material and process parameters, compressing the changeover time to within 30 minutes.

针对特殊行业需求,定制化服务更需体现技术深度。在轨道交通领域,某机车制造商需处理长达24米的车体涂装,制作商创新设计“分段输送+同步喷涂”工艺,通过激光定位系统确保漆膜厚度均匀性达98%以上。而对于精密电子元件涂装,则需采用无尘室级设计,搭配静电除尘装置与低风速循环系统,将颗粒物浓度控制在标准以内。

For special industry needs, customized services need to reflect technical depth even more. In the field of rail transit, a locomotive manufacturer needs to handle a body coating of up to 24 meters. The manufacturer innovatively designed a "segmented conveying+synchronous spraying" process, which ensures a coating thickness uniformity of over 98% through a laser positioning system. For the coating of precision electronic components, a cleanroom level design is required, combined with an electrostatic precipitator and a low wind speed circulation system, to control the particle concentration within the standard.

二、方案设计:模块化组合与智能化集成

2、 Scheme design: modular combination and intelligent integration

定制化流水线的核心在于模块化架构。制作商将前处理、喷涂、烘干、固化等工艺环节拆解为独立模块,客户可根据产能需求灵活配置。例如,某家电企业初期仅需单班生产,制作商先部署基础模块,预留智能升级接口,待产能扩张时快速接入机器人喷涂单元与AI视觉检测系统,实现产能翻倍而无需整体改造。

The core of customized assembly line lies in modular architecture. The manufacturer breaks down the pre-treatment, spraying, drying, curing and other process steps into independent modules, and customers can flexibly configure them according to their production capacity needs. For example, in the initial stage of a household appliance enterprise, only single shift production is required. The manufacturer first deploys basic modules, reserves intelligent upgrade interfaces, and quickly connects robot spraying units and AI visual inspection systems when production capacity expands, achieving double production capacity without the need for overall renovation.

智能化集成是提升方案竞争力的关键。通过数字孪生技术,制作商可在虚拟环境中模拟流水线运行,优化设备布局与物流路径。某重工企业涂装车间经仿真优化后,物料搬运距离缩短40%,能源消耗降低25%。此外,物联网技术的融入使设备具备自我诊断能力,某钢结构制造商的流水线通过实时监测喷枪压力与涂料粘度,将返工率从8%降至1.5%。

Intelligent integration is the key to enhancing the competitiveness of solutions. Through digital twin technology, manufacturers can simulate pipeline operation in a virtual environment, optimize equipment layout and logistics paths. After simulation optimization, the material handling distance in the painting workshop of a certain heavy industry enterprise has been reduced by 40%, and energy consumption has been reduced by 25%. In addition, the integration of IoT technology enables devices to have self diagnostic capabilities. A steel structure manufacturer's assembly line reduced the rework rate from 8% to 1.5% by real-time monitoring of spray gun pressure and paint viscosity.

三、实施落地:精益化施工与全周期服务

3、 Implementation and implementation: Lean construction and full cycle service

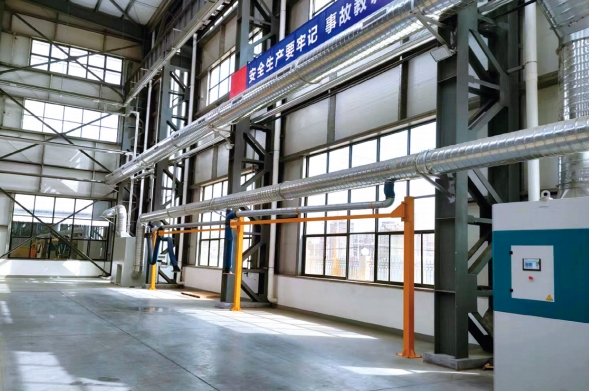

定制化项目的成功与否,取决于实施阶段的精益化管理。制作商采用“装配式施工”模式,将90%的管道、电缆预组装于模块化机架,现场安装周期缩短50%。在某新能源电池厂项目中,制作商通过BIM技术进行管线碰撞检测,避免施工返工,确保项目提前2周交付。

The success of customized projects depends on lean management during the implementation phase. The manufacturer adopts the "assembly construction" mode, pre assembling 90% of the pipes and cables in modular racks, reducing the on-site installation cycle by 50%. In a new energy battery plant project, the manufacturer used BIM technology for pipeline collision detection to avoid construction rework and ensure project delivery 2 weeks ahead of schedule.

全周期服务是定制化价值的延伸。制作商提供从操作培训到产能优化的全生命周期支持。某农机企业流水线投产后,制作商驻场工程师通过调整烘干炉温度曲线,使漆膜附着力提升30%,同时降低燃气消耗。针对设备老化问题,制作商推出“以旧换新”计划,客户可用旧设备折价置换新型节能模块,实现技术迭代零负担。

Full cycle service is an extension of customized value. Manufacturers provide full lifecycle support from operational training to capacity optimization. After the production line of a certain agricultural machinery enterprise was put into operation, the resident engineer of the manufacturer adjusted the temperature curve of the drying furnace to increase the adhesion of the paint film by 30% and reduce gas consumption. In response to the issue of equipment aging, manufacturers have launched a "trade in" program, where customers can trade in old equipment for new energy-saving modules at a discounted price, achieving zero burden in technological iteration.

工业涂装流水线的定制化服务,本质是“工艺需求+技术实现+服务保障”的三维融合。从精准捕捉痛点,到模块化方案设计,再到全周期服务保障,制作商正在重新定义涂装生产线的价值边界。随着柔性制造与工业互联网技术的深化应用,未来的涂装流水线将更智能、更绿色,成为企业数字化转型的重要基石。

The customized service of industrial painting assembly line is essentially a three-dimensional integration of "process requirements+technical implementation+service guarantee". From accurately capturing pain points, to modular solution design, and to full cycle service assurance, manufacturers are redefining the value boundary of coating production lines. With the deepening application of flexible manufacturing and industrial Internet technology, the future painting assembly line will be more intelligent and green, becoming an important cornerstone of enterprise digital transformation.

本文由工业涂装流水线友情奉献.更多有关的知识请点击:http://www.sdcjtz.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.sdcjtz.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号