自动喷粉线:粉末涂料的回收设备有哪些种类,各有什么特点?

喷溢的粉末涂料,可以回收利用,是粉末涂料的重要优势。回收是通过回收设备来完成的。粉末涂料回收设备的种类很多,有旋风分离式、袋 式、弹筒式(滤芯式)、传送带式、薄膜式等。在实际涂装体系中,采用单一设备的很少,多数采用两种或两种以上设备组合在一起的复合型设备。这是因为每种设备既有各自的优点,又有一定的缺点,只用一种设备往往不能得到满意的结果,只有使用复合型设备,才能达到互为补偿的理想结合。在自动化流水线上,用得最多的还是旋风分离器和袋滤器相结合的回收系统。旋风分离器主要回收大部分喷溢的粉末涂料,袋滤器则回收过细的粉末涂料。

The sprayed powder coating can be recycled, which is an important advantage of powder coating. Recycling is accomplished through recycling equipment. There are many types of powder coating recycling equipment, including cyclone separation, bag type, cartridge type (filter type), conveyor belt type, film type, etc. In actual painting systems, few use a single device, and most use composite equipment that combines two or more devices together. This is because each device has its own advantages and disadvantages, and using only one device often cannot achieve satisfactory results. Only by using composite devices can we achieve the ideal combination of mutual compensation. The most commonly used recycling system on automated assembly lines is still the combination of cyclone separators and bag filters. The cyclone separator mainly recovers most of the spilled powder coating, while the bag filter recovers ultra-fine powder coating.

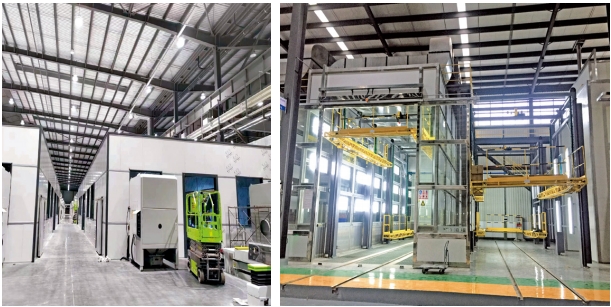

钢桶静电粉末涂装和回收生产线

Steel drum electrostatic powder coating and recycling production line

一、旋风分离式回收设备

1、 Cyclone separation recycling equipment

旋风分离式回收设备是由旋风分离器、鼓风机、振动筛等组成。它像旋风除尘器一样,是利用龙卷风的原理制成的,当高速气流通过倒锥形分离器上部圆筒部分时,气流就在圆筒内部高速旋转,同时在倒锥形内部产生离心力,这种离心力就把较重的粉末涂料颗粒分离出来。当被回收的粉末涂料随着气流被带进分离器时,由于离心力的作用,粗粒子粉末涂料就沉积在锥形筒的底部,得到回收;过细的粉末涂料就随气流从上部带走。这种设备对15μm 以上粉末涂料的回收率高达93%~94%。为了提高回收效率,开发了吹进二次空气的改进型旋风分离设备。改进型二次旋风分离器的气流流向和基本原理示意见图1。高性能旋风分离器和高性能二次旋风分离器回收粉末涂料时,对不同粒度粉末涂料的回收效率的影响见图2。从图中可以看出,经过二次旋风回收以后,对微细粉末涂料,特别是 10μm 以下粉末涂料的回收率有明显的提高。

The cyclone separation recycling equipment is composed of a cyclone separator, a blower, a vibrating screen, etc. It is made using the principle of a tornado, similar to a cyclone dust collector. When high-speed airflow passes through the upper cylindrical part of the inverted cone separator, the airflow rotates at high speed inside the cylinder, while generating centrifugal force inside the inverted cone. This centrifugal force separates heavier powder coating particles. When the recycled powder coating is carried into the separator by the airflow, due to the centrifugal force, the coarse particle powder coating settles at the bottom of the conical cylinder and is recycled; The ultra-fine powder coating is carried away from the upper part by the airflow. This device has a recovery rate of up to 93% to 94% for powder coatings over 15 μ m. In order to improve the recycling efficiency, an improved cyclone separation equipment that blows in secondary air has been developed. Diagram 1 shows the airflow direction and basic principle of the improved secondary cyclone separator. The impact of high-performance cyclone separators and high-performance secondary cyclone separators on the recovery efficiency of powder coatings with different particle sizes is shown in Figure 2. From the figure, it can be seen that after the secondary cyclone recovery, the recovery rate of fine powder coatings, especially powder coatings below 10 μ m, has been significantly improved.

图1 改进型二次旋风分离器的气流流向和基本原理示意

Figure 1 Schematic diagram of the airflow direction and basic principle of the improved secondary cyclone separator

1-干净空气出口;2-二次空气室;3-二次空气喷嘴;4-二次空气入口;5-未涂着上去的粉末涂料和空气;6-二次旋风分离室;7-一次旋风分离室;8-挡板;9-回收粉末室;A-A 断面为含粉末气流流动图

1. Clean air outlet; 2- Secondary air chamber; 3- Secondary air nozzle; 4- Secondary air inlet; 5- Powder coating and air that have not been applied; 6-Secondary cyclone separation chamber; 7-primary cyclone separation chamber; 8-baffle; 9-Recycling powder room; The A-A section is a flow diagram of powder containing airflow

图2 高性能旋风分离器和高性能二次旋风分离器对不同粉末粒度回收效率的影响

Figure 2: The Influence of High Performance Cyclone Separators and High Performance Secondary Cyclone Separators on the Recovery Efficiency of Different Powder Particle Sizes

1-高性能二次旋风分离器;2-高性能旋风分离器

1. High performance secondary cyclone separator; 2-High performance cyclone separator

这种高性能二次旋风分离器的基本原理是:第一次旋风分离回收后排放的含有微细粉末涂料气流中,从上部吹进二次空气,通过喷嘴变成高速气流,进行第二次旋风分离,使微细粉末涂料进一步分离出来。改进型旋风分离器对10pm粉末涂料的回收率达到 99.9%,回收率比前者提高很多。回收的粉末涂料还要经过振动筛除去机械杂质后,再与新粉末涂料混合后再用。这种回收设备有以下优点:

The basic principle of this high-performance secondary cyclone separator is that the airflow containing fine powder coating discharged after the first cyclone separation and recovery is blown into the secondary air from the upper part, which is then transformed into a high-speed airflow through a nozzle for the second cyclone separation, further separating the fine powder coating. The improved cyclone separator achieved a recovery rate of 99.9% for 10pm powder coating, which is much higher than the former. The recycled powder coating needs to go through a vibrating screen to remove mechanical impurities, and then be mixed with new powder coating before use. This recycling device has the following advantages:

(1)?粉末涂料的回收率高;

(1)? The recovery rate of powder coating is high;

(2)设备的安装位置比较随便;

(2) The installation location of the equipment is relatively casual;

(3)?吸引空气的位置可以任意选择。

(3)? The location that attracts air can be chosen arbitrarily.

设备有存在以下的缺点:

The device has the following drawbacks:

(1)设备的占地面积大,高度高;

(1) The equipment has a large footprint and high height;

(2)设备运转时噪音较大;

(2) The equipment produces loud noise during operation;

(3)有一部分粉尘排放到大气中去。

(3) A portion of the dust is emitted into the atmosphere.

为了克服粉尘对大气的污染,在旋风分离器的后面安装袋滤器,这种组合体系更好。

To overcome the pollution of dust to the atmosphere, a bag filter is installed behind the cyclone separator, which is a better combination system.

二、袋滤式回收设备

2、 Bag filter recycling equipment

袋滤式回收设备是由袋滤器、振荡器、抽风机、振动筛等组成(见图3)。这种设备的基本原理是当带有喷溢粉末涂料的气流通过袋滤器时,只有空气透过滤布,粉末涂料却通不过去,从而使粉末涂料从空气中分离出来,分离的粉末涂料进行收集,然后经振动筛过筛除去杂质,再与新粉末涂料混合后再用。这种设备的粉末涂料回收效率达99.9%,回收效率决定于滤布的材质和孔隙,用于滤布的材料有毛毡、帆布、尼龙布、涤纶布和其他合成纤维材料等。

The bag filter recycling equipment is composed of bag filters, oscillators, exhaust fans, vibrating screens, etc. (see Figure 3). The basic principle of this device is that when the airflow with spilled powder coating passes through the bag filter, only the air passes through the filter cloth, but the powder coating cannot pass through, so that the powder coating is separated from the air. The separated powder coating is collected, then sieved through a vibrating screen to remove impurities, and mixed with new powder coating before use. The powder coating recovery efficiency of this equipment reaches 99.9%, which depends on the material and pores of the filter cloth. Materials used for filter cloth include felt, canvas, nylon cloth, polyester cloth, and other synthetic fiber materials.

图3 袋滤式粉末涂料回收设备

Figure 3 Bag filter powder coating recycling equipment

1-电机;2-抽风机;3-干净空气出口;4-滤布;5-粉末留在滤布外面;6-振荡器;7-粉末涂料;8-回收;9-未涂着上去的粉末涂料

1. Motor; 2- Exhaust fan; 3- Clean air outlet; 4- Filter cloth; 5- Powder left outside the filter cloth; 6-oscillator; 7-Powder coating; 8- Recycling; 9- Powder coating not applied

为了保证滤布的正常过滤功能,必须及时清扫附着于滤布上的粉末涂料。清扫的方法有两种,一种是振荡法;另一种是压缩空气反吹法。振荡法是用振荡装置定时振荡滤布,振掉附着在滤布上的粉末涂料。压缩空气反吹法是定时从袋滤器的滤布外面,往里吹压缩空气,把附着在滤布上的粉末涂料吹掉,保证滤布畅通。在压缩空气反吹法中使用的空气流的速度为5~10m/s。这种设备有以下优点:

In order to ensure the normal filtering function of the filter cloth, it is necessary to promptly clean the powder coating attached to the filter cloth. There are two methods for cleaning, one is the oscillation method; Another method is the compressed air blowback method. The oscillation method is to use an oscillation device to oscillate the filter cloth at regular intervals, and shake off the powder coating attached to the filter cloth. The compressed air back blowing method is to periodically blow compressed air from the outside of the filter cloth of the bag filter into the inside, blowing off the powder coating attached to the filter cloth to ensure its smoothness. The velocity of the air flow used in the compressed air blowback method is 5-10m/s. This device has the following advantages:

(1)粉末涂料的回收率高,排放空气比较干净;

(1) The recovery rate of powder coating is high, and the air emissions are relatively clean;

(2)比起旋风分离式回收设备,运转时嗓音比较小;

(2) Compared to cyclone separation recycling equipment, the noise during operation is relatively low;

(3)设备所占面积和体积比旋风分离式回收设备小。

(3) The area and volume occupied by the equipment are smaller than those of cyclone separation recycling equipment.

缺点是设备清扫和换色比较困难。当不要求回收粉末涂料时可以单独使用,一般情况下与旋风分离器配套使用。

The disadvantage is that it is difficult to clean and change the color of the equipment. When powder coating recycling is not required, it can be used alone and is generally used in conjunction with a cyclone separator.

三、弹筒(滤芯)式回收设备

3、 Bullet tube (filter element) type recycling equipment

弹筒(滤芯)式回收粉末涂料设备是袋滤式回收设备的改进型,其回收的基本原理是一样的,主要区别在于过滤装置的小型化和高效化。弹筒(滤芯)式过滤器的结构及原理示意见图4,装有弹筒(滤芯)式过滤器粉末涂料回收设备的涂装系统见图5。这种回收粉末系统的关键设备是弹筒(滤芯)式过滤器,直接可安放在喷粉室内部。

The drum (filter element) type powder coating recycling equipment is an improved version of the bag filter type recycling equipment, and its basic principle of recycling is the same, with the main difference being the miniaturization and high efficiency of the filtering device. The structure and principle diagram of the cartridge (filter element) filter are shown in Figure 4, and the coating system equipped with the cartridge (filter element) filter powder coating recycling equipment is shown in Figure 5. The key equipment of this powder recycling system is a cartridge (filter element) filter, which can be directly placed inside the powder spraying room.

图4 弹筒(滤芯)式过滤器结构及原理示意图

Figure 4 Schematic diagram of the structure and principle of the cartridge (filter element) filter

(1)运动状态;(2)清洗状态

(1) Movement status; (2) Cleaning status

1-干净空气出口;2-吹气管;3-滤芯;4-含粉末涂料入口;5-吹进空气;6-粉末涂料

1. Clean air outlet; 2. Blow the trachea; 3- Filter element; 4- Inlet containing powder coating; 5- Blow in air; 6-Powder coating

图5 装有弹筒(滤芯)式过滤器粉末涂料回收设备的涂装系统

Figure 5 Coating system equipped with bullet tube (filter element) filter powder coating recycling equipment

1-喷枪;2-电源;3-喷粉室;4-被涂物;5-弹筒(滤芯)式粉末回收装置;6-旋风分离器;7-旋转阀;8-供粉末槽;9-泵;10-容量送料器

1. Spray gun; 2- Power supply; 3- Powder spraying room; 4- Coated material; 5-cartridge (filter) type powder recovery device; 6-Cyclone separator; 7-Rotary valve; 8-Powder supply tank; 9-Pump; 10 Capacity feeder

当喷溢的粉末涂料随空气流进入弹筒(滤芯)式过滤器内部时,由于滤芯的过滤作用,粉末涂料就不能透过滤芯,附着在滤芯外壁或者落到滤芯底部,只有空气透过滤芯壁,排放到外部。因为滤芯顶部装有一个喷嘴,定时地往滤芯内部反吹压缩空气,把附着在滤芯外壁的粉末涂料吹下来,落到滤芯的下面。当回收粉末涂料达到一定量时,通过倾斜板把粉末涂料收集到喷粉室底部,经过过筛,除去机械杂质,跟新粉混合后使用。另外,滤芯达到规定使用寿命以后,及时更换新滤芯,以确保回收效果。这种设备有以下优点:

When the sprayed powder coating enters the interior of the cartridge (filter element) filter with the air flow, due to the filtering effect of the filter element, the powder coating cannot pass through the filter element and adheres to the outer wall of the filter element or falls to the bottom of the filter element. Only the air passes through the filter element wall and is discharged to the outside. Because the top of the filter element is equipped with a nozzle that periodically blows compressed air back into the interior of the filter element, blowing off the powder coating attached to the outer wall of the filter element and falling underneath it. When the amount of recycled powder coating reaches a certain level, the powder coating is collected at the bottom of the powder spraying chamber through a tilted plate, sieved to remove mechanical impurities, and mixed with new powder before use. In addition, after the filter element reaches the specified service life, it should be replaced with a new filter element in a timely manner to ensure the recycling effect. This device has the following advantages:

(1)?设备的占地空间小,弹筒(滤芯)式过滤器可以直接安装在喷粉室内部;

(1)? The equipment has a small footprint, and the cartridge (filter element) filter can be directly installed inside the powder spraying room;

(2)粉末涂料回收系统的回路很短,涂料的物性变化小,涂料的损失也少;

(2) The circuit of the powder coating recycling system is very short, the physical properties of the coating change little, and the loss of the coating is also minimal;

(3)不存在粉尘爆炸的危险,涂装的安全性高;

(3) There is no risk of dust explosion, and the safety of painting is high;

(4)过滤器的滤芯更换方便,换涂料颜色和品种简单。

(4) The filter element of the filter is easy to replace, and changing the color and variety of the coating is simple.

缺点是粉末涂料的回收容量有限,不适用于大批量自动化流水线上使用。这种设备基本上是单独使用。

The disadvantage is that the recycling capacity of powder coatings is limited and not suitable for use on large-scale automated assembly lines. This type of device is basically used alone.

四、传送带式回收设备

4、 Conveyor belt recycling equipment

传送带式粉末涂料回收设备是通过安装在喷粉室下面,用过滤布制成,并不停地运转的传送带回收粉末涂料。当喷粉室内进行喷涂时,喷溢的粉末涂料就随气流进入回收设备,空气就透过过滤布制成的传送带向外排放,粉末涂料就被传送带捕集,并由传送带送到真空吸粉器处,把粉末从传送带吸下,送往旋风分离器和袋滤器进行回收(见图6)。

The conveyor belt type powder coating recycling equipment is installed under the powder spraying room, made of filter cloth, and runs continuously to recycle powder coating. When spraying in the powder spraying room, the spilled powder coating enters the recovery equipment with the airflow, and the air is discharged outward through the conveyor belt made of filter cloth. The powder coating is captured by the conveyor belt and sent to the vacuum powder absorber by the conveyor belt. The powder is sucked down from the conveyor belt and sent to the cyclone separator and bag filter for recovery (see Figure 6).

1-喷粉室;2-过滤传送带;3-喷枪;4-真空吸粉器;5-往复移行机;6-排风过滤器;7-排风扇;8-高性能过滤器;9-微型旋风分离器;10-旋转阀;11-振动筛;12-涂料槽;13-超细粉收集器;14-袋滤器;15-安全过滤器;16-回收空气;17-涂装控制柜;18-定量供粉装置;19-反冲喷嘴;20-换色器

1. Powder spraying room; 2- Filter conveyor belt; 3- Spray gun; 4- Vacuum powder suction device; 5-reciprocating moving machine; 6-Exhaust air filter; 7-exhaust fan; 8-High performance filters; 9-Micro cyclone separator; 10- Rotary valve; 11- vibrating screen; 12- Paint tank; 13- Ultra fine powder collector; 14- Bag filter; 15- Safety filter; 16- Recycling air; 17- Coating control cabinet; 18- Quantitative powder supply device; 19- Backwash nozzle; 20- Color changer

回收粉末涂料经振动筛过筛除去机械杂质,再与新粉末按比例混合后,供涂装体系使用。从喷粉室排放的空气是经过滤器净化以后排放大气。这种设备可以单独使用,也可以和其他回收设备组合后使用,图6是同旋风分离器和袋滤器组合使用的例子。这种设备有以下优点:

Recycled powder coating is sieved through a vibrating screen to remove mechanical impurities, and then mixed with new powder in proportion for use in the coating system. The air discharged from the powder spraying room is purified by a filter before being released into the atmosphere. This device can be used alone or in combination with other recycling equipment. Figure 6 shows an example of using it in combination with a cyclone separator and a bag filter. This device has the following advantages:

(1)喷粉室的换气量小(5m^2/min),空气的流动速度分布均匀,喷枪喷出的粉末喷束也比较均匀。

(1) The ventilation rate of the powder spraying room is small (5m ^ 2/min), the air flow velocity is evenly distributed, and the powder jet sprayed by the spray gun is also relatively uniform.

(2)?换气扇的动力消耗小,属于节能型。

(2)? The power consumption of the ventilation fan is low and it belongs to the energy-saving type.

(3)如果喷粉室内部的顶部和侧面内壁,采用难于附着粉末涂料的特材料,将为过滤式传送带的换色和换品种带来方便。

(3) If special materials that are difficult to adhere to powder coatings are used on the top and side walls inside the powder spraying room, it will bring convenience to the color and variety change of the filter conveyor belt.

缺点是连同设备的附属系统在内,整个回收系统结构比较复杂。

The disadvantage is that the entire recycling system structure, including the ancillary systems of the equipment, is relatively complex.

五、薄膜式回收设备

5、 Thin film recycling equipment

薄膜式回收设备涂装系统见图7,喷粉室内部的所有壁面都由透明塑料薄膜覆盖,喷粉室外部是由旋风分离器和袋滤器组成的完整的粉末涂料回收系统。喷粉室的框架由管子构成,上部安放新薄膜,底部安放用过的薄膜,当需要换色时,用过的薄膜卷起来回收粉末,同时重新铺新薄膜。为了回收粉末涂料,喷粉室底部设计成圆筒状,再与旋风分离器和袋滤器相连结。这种回收系统的优点是换色时间短,10分钟左右可以换色,适用于换色多的涂装体系。

The coating system of the film recycling equipment is shown in Figure 7. All walls inside the powder spraying room are covered with transparent plastic film, and the outside of the powder spraying room is a complete powder coating recycling system composed of a cyclone separator and a bag filter. The frame of the powder spraying room is composed of pipes, with a new film placed at the top and a used film placed at the bottom. When a color change is needed, the used film is rolled up to recover the powder and a new film is laid. In order to recycle powder coating, the bottom of the powder spraying chamber is designed in a cylindrical shape and connected to a cyclone separator and a bag filter. The advantage of this recycling system is its short color change time, which can be changed in about 10 minutes, making it suitable for coating systems with multiple color changes.

本文由 自动喷粉线 友情奉献.更多有关的知识请点击 http://www.sdcjtz.com/ 真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the automatic powder spraying line For more related knowledge, please click http://www.sdcjtz.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Stay tuned

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号