网带通过式抛丸机的安装注意事项

1. 安全操作:在进行安装之前,确保所有相关人员都已经了解和熟悉设备的安装操作要求,并佩戴适当的防护装备,如安全帽、手套、安全鞋等。

1. Safe operation: Before installation, ensure that all relevant personnel have understood and familiarized themselves with the installation requirements of the equipment, and wear appropriate protective equipment, such as helmets, gloves, safety shoes, etc.

2. 设备定位:选择合适的安装位置,确保设备的稳定性和可靠性。考虑设备的尺寸、重量和运行时的振动,并保证设备有足够的空间用于安全操作和维修。

2. Equipment positioning: Choose a suitable installation location to ensure the stability and reliability of the equipment. Consider the size, weight, and vibration of the equipment during operation, and ensure that there is sufficient space for safe operation and maintenance.

3. 基础支撑:对设备进行适当的基础支撑,如基础垫板、螺栓固定等。确保设备在运行时不会发生移动或晃动,同时确保设备与地面保持一定的距离,以便进行维护和清理。

3. Basic support: Provide appropriate basic support for the equipment, such as foundation pads, bolt fixation, etc. Ensure that the equipment does not move or shake during operation, and maintain a certain distance from the ground for maintenance and cleaning.

4. 输送系统安装:安装网带输送系统时,确保网带正确安装并调整张力。检查导向滚筒、托辊、链条和机械连接件的安装质量和准确性。

4. Installation of conveyor system: When installing the mesh belt conveyor system, ensure that the mesh belt is installed correctly and adjust the tension. Check the installation quality and accuracy of guide rollers, idlers, chains, and mechanical connectors.

5. 电气连接:进行设备的电气连接时,确保符合相关的安全标准和规范。检查电气线路和接线盒的连接是否牢固,并确保接地线与设备良好连接。

5. Electrical connection: When making electrical connections to equipment, ensure compliance with relevant safety standards and regulations. Check if the electrical wiring and junction box connections are secure, and ensure that the grounding wire is well connected to the equipment.

6. 润滑系统:对设备的润滑系统进行正确的安装和调试,确保润滑油路通畅,并检查润滑油的供给是否正常。

6. Lubrication system: Install and debug the lubrication system of the equipment correctly, ensure smooth lubrication oil circuit, and check whether the supply of lubricating oil is normal.

7. 安装调试:在设备安装完成后,进行初步的安装调试,检查设备的各项功能是否正常,如传动系统、进出料系统、清理系统等。

7. Installation and debugging: After the equipment installation is completed, preliminary installation and debugging are carried out to check whether the various functions of the equipment are normal, such as the transmission system, inlet and outlet system, cleaning system, etc.

上一篇:涂装生产线设备结构特点介绍

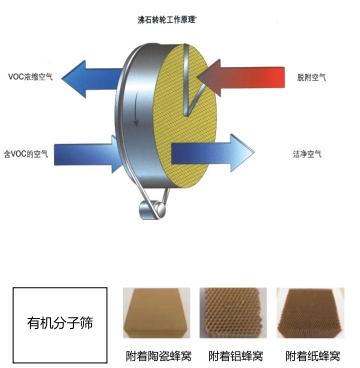

下一篇:沸石转轮中VOCs残留的处理

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号