工厂焊烟超标 “突围战”:多工位除尘设备能否力挽狂澜?

在工厂生产场景中,焊烟超标不仅威胁工人健康,还可能违反相关环境规定。面对这一难题,寻求有效的解决方案迫在眉睫。而多工位焊烟除尘设备作为近年来常见的应对手段,其实际效果备受关注,这需要从焊烟超标的根源治理到设备作用机制进行全面分析。

In factory production scenarios, excessive welding fumes not only threaten workers' health, but may also violate relevant environmental regulations. Faced with this difficult problem, it is urgent to seek effective solutions. As a common response method in recent years, multi station welding smoke and dust removal equipment has attracted much attention for its actual effectiveness. This requires a comprehensive analysis from the root cause of welding smoke exceeding standards to the mechanism of equipment operation.

焊烟超标首先要从源头寻找原因。焊接工艺的选择对焊烟产生量影响巨大。一些传统焊接方法,在高温作业时会产生大量含有金属氧化物、有害气体的烟尘。若工厂使用的焊接材料质量不佳,杂质较多,也会加剧焊烟的产生。此外,工厂车间的布局设计不合理,通风条件差,无法及时将产生的焊烟排出室外,使得焊烟在车间内积聚,导致浓度超标。

Welding smoke exceeding the standard first needs to find the cause from the source. The choice of welding process has a significant impact on the amount of welding fumes produced. Some traditional welding methods generate a large amount of smoke and dust containing metal oxides and harmful gases during high-temperature operations. If the welding materials used in the factory are of poor quality and contain a lot of impurities, it will also exacerbate the generation of welding fumes. In addition, the layout design of the factory workshop is unreasonable, the ventilation conditions are poor, and the generated welding smoke cannot be discharged outdoors in a timely manner, resulting in the accumulation of welding smoke in the workshop and exceeding the concentration limit.

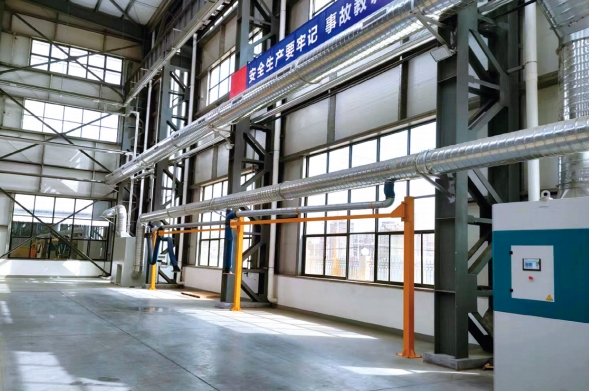

针对这些问题,从源头进行改进是关键。工厂可以尝试优化焊接工艺,采用新型的焊接技术,这些技术往往在减少焊烟产生方面具有显著效果。同时,严格把控焊接材料的质量,选择低尘、低毒的焊接材料,从源头上降低焊烟的产生量。在车间布局上,合理规划焊接工位,确保工位之间有足够的空间,并且加强车间的整体通风设计,安装通风管道和排风扇,加快空气流通,将产生的焊烟及时排出。

Improving from the source is key to addressing these issues. Factories can try to optimize welding processes and adopt new welding technologies, which often have significant effects in reducing welding fumes. At the same time, strictly control the quality of welding materials, choose low dust and low toxicity welding materials, and reduce the generation of welding fumes from the source. In terms of workshop layout, reasonable planning of welding stations should be carried out to ensure sufficient space between stations, and the overall ventilation design of the workshop should be strengthened by installing ventilation ducts and exhaust fans to accelerate air circulation and timely discharge of welding fumes.

多工位焊烟除尘设备的工作原理和实际效果是解决焊烟超标问题的重点。这类设备通常通过强大的吸力,将各个焊接工位产生的焊烟收集起来。设备配备的高效过滤系统是关键,它能够拦截不同粒径的烟尘颗粒,包括细小的有害粉尘,经过层层过滤,将净化后的空气排放到车间内或室外。在实际使用中,多工位焊烟除尘设备的效果取决于多个因素。设备的吸力大小直接影响焊烟的收集效率,如果吸力不足,距离较远的工位产生的焊烟可能无法被有效吸入。过滤系统的性能也至关重要,若过滤材料质量差或使用时间过长未及时更换,过滤效果会大打折扣,导致排出的空气中仍含有较多污染物。

The working principle and actual effect of multi station welding smoke dust removal equipment are the key to solving the problem of welding smoke exceeding the standard. This type of equipment usually collects the welding fumes generated by each welding station through strong suction. The efficient filtration system equipped with the equipment is key, as it can intercept smoke particles of different sizes, including small harmful dust. After layer by layer filtration, the purified air is discharged into the workshop or outdoors. In practical use, the effectiveness of multi station welding smoke and dust removal equipment depends on multiple factors. The suction force of the equipment directly affects the collection efficiency of welding fumes. If the suction force is insufficient, the welding fumes generated at distant workstations may not be effectively sucked in. The performance of the filtering system is also crucial. If the quality of the filtering material is poor or if it is not replaced in a timely manner after a long period of use, the filtering effect will be greatly reduced, resulting in the exhaust air still containing a lot of pollutants.

要确保多工位焊烟除尘设备发挥最佳作用,正确的安装和日常维护必不可少。安装时,需要根据车间的实际布局和焊接工位的分布,合理规划吸尘口的位置和数量,保证每个工位产生的焊烟都能被及时捕捉。在日常使用中,定期检查设备的吸力是否正常,及时清理吸尘管道内积聚的灰尘,防止管道堵塞影响吸尘效果。按照规定的时间更换过滤材料,确保过滤系统始终保持高效的过滤能力。此外,还要对设备的电机、风机等关键部件进行定期保养,延长设备的使用寿命。

Proper installation and daily maintenance are essential to ensure the optimal performance of multi station welding smoke and dust removal equipment. During installation, it is necessary to plan the position and quantity of the suction port reasonably based on the actual layout of the workshop and the distribution of welding stations, to ensure that the welding smoke generated by each station can be captured in a timely manner. In daily use, regularly check whether the suction of the equipment is normal, promptly clean the accumulated dust in the suction pipe, and prevent pipe blockage from affecting the suction effect. Replace the filter material according to the prescribed time to ensure that the filtration system always maintains efficient filtration capacity. In addition, regular maintenance should be carried out on key components such as motors and fans of the equipment to extend its service life.

除了使用多工位焊烟除尘设备,工厂还应建立完善的管理制度。制定严格的焊接操作规范,要求工人按照标准流程进行作业,减少因操作不当产生的额外焊烟。加强对车间空气质量的监测,定期检测焊烟浓度,及时掌握车间内的环境状况。同时,为工人配备专业的防护用品,如防尘口罩、防护面罩等,在设备未能完全解决问题的情况下,最大限度地保护工人的身体健康。

In addition to using multi station welding smoke and dust removal equipment, the factory should also establish a sound management system. Establish strict welding operation standards, requiring workers to follow standard procedures to reduce additional welding fumes caused by improper operation. Strengthen the monitoring of workshop air quality, regularly detect welding smoke concentration, and timely grasp the environmental conditions in the workshop. At the same time, provide workers with professional protective equipment such as dust masks, face shields, etc., to maximize the protection of workers' physical health in the event that the equipment fails to fully solve the problem.

工厂焊烟超标问题的解决需要综合施策,从源头治理到设备应用,再到管理强化缺一不可。多工位焊烟除尘设备若能合理安装、正确使用并做好维护,确实能够在很大程度上降低车间内的焊烟浓度,但不能将其视为唯一的解决办法。只有将多种措施有机结合,才能打赢这场焊烟超标 “突围战”,为工厂创造一个健康、安全的生产环境。

The solution to the problem of excessive welding smoke in factories requires comprehensive measures, from source control to equipment application, and then to strengthened management. If the multi station welding smoke dust removal equipment can be installed, used correctly, and maintained properly, it can indeed greatly reduce the welding smoke concentration in the workshop, but it cannot be regarded as the only solution. Only by organically combining multiple measures can we win the breakthrough battle of welding smoke exceeding standards and create a healthy and safe production environment for the factory.

本文由多工位焊烟除尘设备友情奉献.更多有关的知识请点击:http://www.sdcjtz.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.sdcjtz.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号