机箱机柜喷塑设备流水线的三个重要工艺流程

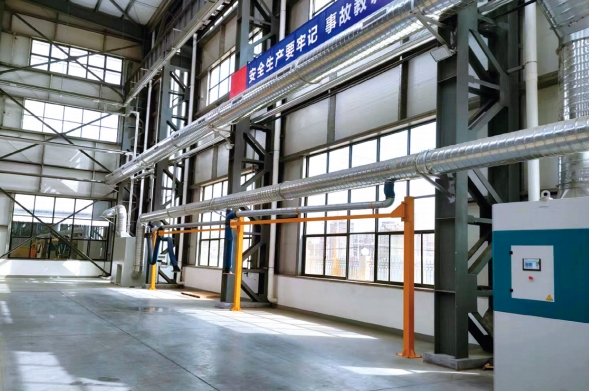

自动喷塑设备流水线是一种高效的喷涂输送设备,其施工工艺主要包括三个核心步骤:工件预处理、工件预热和喷涂。每一个步骤都至关重要,对于最终涂层的质量和性能有着决定性的影响。

The automatic spray molding equipment assembly line is an efficient spray conveying equipment, and its construction process mainly includes three core steps: workpiece pretreatment, workpiece preheating, and spraying. Each step is crucial and has a decisive impact on the quality and performance of the final coating.

一、工件预处理

1、 Workpiece pretreatment

预处理是喷涂前的首要任务,主要目的是清除工件表面的油污、铁锈或其他涂层,确保基体金属完全裸露。这一步骤至关重要,因为它为后续的喷涂过程提供了良好的附着基础。

Pre treatment is the primary task before spraying, with the main purpose of removing oil stains, rust, or other coatings from the surface of the workpiece, ensuring that the base metal is completely exposed. This step is crucial as it provides a good adhesion foundation for the subsequent spraying process.

二、工件预热

2、 Workpiece preheating

预热是喷涂过程中的关键环节,其时间根据工件的规格和数量而定。厚壁、数量多的工件需要更长的预热时间,而薄壁、数量少的工件则相对较短。这是因为不同重量的工件在加热时所需的总热量不同,必须确保每个工件达到热平衡状态。预热温度对热喷涂效果至关重要,过低会导致涂层不均匀,过高则可能引发流挂和炭化现象,影响涂膜性能。

Preheating is a crucial step in the spraying process, and its time depends on the specifications and quantity of the workpiece. Thick walled and large quantity workpieces require longer preheating time, while thin-walled and small quantity workpieces are relatively shorter. This is because the total heat required for heating workpieces of different weights varies, and it is necessary to ensure that each workpiece reaches a thermal equilibrium state. Preheating temperature is crucial for the effectiveness of thermal spraying. If it is too low, it can lead to uneven coating, while if it is too high, it may cause sagging and carbonization, affecting the performance of the coating film.

三、喷涂

3、 Spray coating

喷涂是自动喷塑设备流水线的核心环节,需要精确控制多个参数。首先是喷粉量,这是决定涂层厚度和均匀度的关键因素。热喷涂时,喷粉量通常较大,一般在200~300g/min之间。此外,喷枪与工件的距离、喷涂次数以及喷枪的运行轨迹也必须精确掌握。距离过远会导致上粉率低,距离过近则可能引发反弹。喷涂次数和喷枪运行轨迹则直接影响涂层的均匀性和厚度。

Spraying is the core part of the automatic spraying equipment assembly line, which requires precise control of multiple parameters. The first factor is the amount of powder sprayed, which is the key factor determining the thickness and uniformity of the coating. During thermal spraying, the amount of powder sprayed is usually large, usually between 200~300g/min. In addition, the distance between the spray gun and the workpiece, the number of spraying times, and the running trajectory of the spray gun must also be accurately controlled. Distance too far can lead to low powder loading rate, while distance too close may trigger rebound. The number of sprays and the trajectory of the spray gun directly affect the uniformity and thickness of the coating.

除了以上参数,粉末的回收也是喷涂过程中不可忽视的一环。热喷涂时,上粉率通常只有50%左右,剩余的粉末会散落于喷涂室内或空气中。为了控制粉尘污染,喷涂室的集尘吸风口应设置在喷涂室上部,并根据被涂工件的特点和喷涂施工方式进行专门设计。

In addition to the above parameters, powder recovery is also an indispensable part of the spraying process. During thermal spraying, the powder loading rate is usually only about 50%, and the remaining powder will scatter inside the spraying room or in the air. In order to control dust pollution, the dust collection and suction port of the spraying room should be set at the upper part of the spraying room, and specially designed according to the characteristics of the coated workpiece and the spraying construction method.

上一篇:车间焊烟除尘设备知识介绍

下一篇:多工位焊接烟尘净化系统的组成

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号