涂装生产线常见问题及解决办法

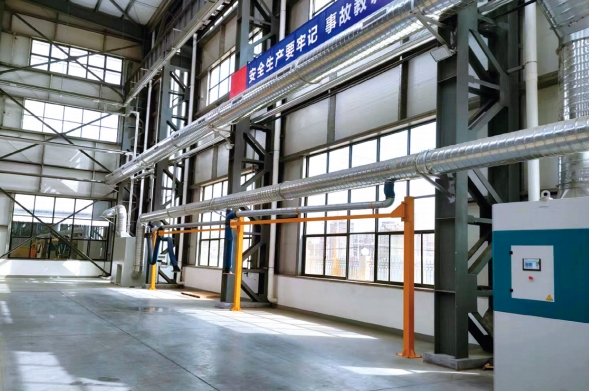

涂装设备、工作环境、涂装管理、涂装工艺和材料直接关系到涂装生产线的生产效率。在这个过程中,涂装设备的工艺布局对涂装流水线的使用有着重要的影响。这里我们将解释涂层设备工艺布局中的典型错误。

涂装设备、工作环境、涂装管理、涂装工艺和材料直接关系到涂装生产线的生产效率。在这个过程中,涂装设备的工艺布局对涂装流水线的使用有着重要的影响。这里我们将解释涂层设备工艺布局中的典型错误。

The painting equipment, working environment, painting management, painting process, and materials are directly related to the production efficiency of the painting production line. In this process, the process layout of the painting equipment has a significant impact on the use of the painting assembly line. Here we will explain typical errors in the process layout of coating equipment.

1、输送设计程序达不到有些设计没有考虑涂装设备的悬挂方式(不同的涂装挂件应考虑不同的悬挂方式)、悬挂距离、上下坡度和水平转弯距离的干扰、废品率、涂装设备利用率、产品的峰值生产能力等。也不考虑生产时间。这将导致生产不符合设计指南。

1. The conveying design program cannot achieve some designs that do not consider the suspension method of the painting equipment (different painting pendants should consider different suspension methods), suspension distance, interference from up and down slopes and horizontal turning distances, scrap rate, painting equipment utilization rate, peak production capacity of products, etc. Not considering production time either. This will result in production not meeting the design guidelines.

2、涂装设备工艺时间有偏差为了降低成本,一些设计师经常通过减少加工时间来实现他们的目标。常见的有:

2. In order to reduce costs, some designers often achieve their goals by reducing processing time due to deviations in the process time of painting equipment. Common ones include:

1 .涂装生产线前的过渡期不够长,会导致液体串线;2.固化过程中没有考虑具体的加热时间,导致固化不良。3.油漆流平时间不足,导致漆膜流平不充分;4.固化后的冷却时间不够,导致涂装过程中工件(或下部)过热或固定不充分。

1 The transition period before the painting production line is not long enough, which can lead to liquid stringing; 2. The specific heating time was not considered during the curing process, resulting in poor curing. 3. Insufficient paint leveling time leads to insufficient leveling of the paint film; 4. Insufficient cooling time after curing can cause overheating or insufficient fixation of the workpiece (or lower part) during the coating process.

3、涂装设备选择不当由于不同产品的不同要求,设备选择也不同,各种涂装设备各有利弊。如果无法向用户解释设计,客户会发现制造完成后涂层生产线不满意。例如,粉末喷涂干燥隧道采用空气幕隔热,有清洁要求的工件不安装净化设备。这种错误是涂装设备工艺布局中最常见的错误。

3. Improper selection of painting equipment is due to the different requirements of different products, and the selection of equipment is also different. Each painting equipment has its own advantages and disadvantages. If the design cannot be explained to the user, the customer will find that the coating production line is not satisfied after manufacturing is completed. For example, powder spray drying tunnels use air curtains for insulation, and workpieces with cleaning requirements do not have purification equipment installed. This type of error is the most common mistake in the layout of painting equipment processes.

4、未考虑涂装设备节能问题

4. Not considering the energy-saving issue of painting equipment

目前,这种能源的价格变化相对较快。然而,如果在设计中不考虑这些问题,用户的生产成本将会更高,一些用户将不得不在短时间内重建和购买设备。这不是顾客想要的。涂装设备工艺布局设计的质量对涂装生产线的使用至关重要。如果涂装设备的工艺布局不当,即使每一件设备都制造得很好,整个涂装生产线也不容易使用。因此,在设计时,我们必须避免上述常见错误,从而造成不必要的损失!

At present, the price of this energy source changes relatively quickly. However, if these issues are not considered in the design, the production cost for users will be higher, and some users will have to rebuild and purchase equipment in a short period of time. This is not what the customer wants. The quality of process layout design for painting equipment is crucial for the use of painting production lines. If the process layout of the painting equipment is improper, even if each piece of equipment is manufactured well, the entire painting production line is not easy to use. Therefore, in design, we must avoid the common errors mentioned above, which can cause unnecessary losses!

本文由 工业涂装流水线 友情奉献.更多有关的知识请点击 http://www.sdcjtz.com/ 真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the industrial painting assembly line For more related knowledge, please click http://www.sdcjtz.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.涂装设备、工作环境、涂装管理、涂装工艺和材料直接关系到涂装生产线的生产效率。在这个过程中,涂装设备的工艺布局对涂装流水线的使用有着重要的影响。这里我们将解释涂层设备工艺布局中的典型错误。

The painting equipment, working environment, painting management, painting process, and materials are directly related to the production efficiency of the painting production line. In this process, the process layout of the painting equipment has a significant impact on the use of the painting assembly line. Here we will explain typical errors in the process layout of coating equipment.

1、输送设计程序达不到有些设计没有考虑涂装设备的悬挂方式(不同的涂装挂件应考虑不同的悬挂方式)、悬挂距离、上下坡度和水平转弯距离的干扰、废品率、涂装设备利用率、产品的峰值生产能力等。也不考虑生产时间。这将导致生产不符合设计指南。

1. The conveying design program cannot achieve some designs that do not consider the suspension method of the painting equipment (different painting pendants should consider different suspension methods), suspension distance, interference from up and down slopes and horizontal turning distances, scrap rate, painting equipment utilization rate, peak production capacity of products, etc. Not considering production time either. This will result in production not meeting the design guidelines.

2、涂装设备工艺时间有偏差为了降低成本,一些设计师经常通过减少加工时间来实现他们的目标。常见的有:

2. In order to reduce costs, some designers often achieve their goals by reducing processing time due to deviations in the process time of painting equipment. Common ones include:

1 .涂装生产线前的过渡期不够长,会导致液体串线;2.固化过程中没有考虑具体的加热时间,导致固化不良。3.油漆流平时间不足,导致漆膜流平不充分;4.固化后的冷却时间不够,导致涂装过程中工件(或下部)过热或固定不充分。

1 The transition period before the painting production line is not long enough, which can lead to liquid stringing; 2. The specific heating time was not considered during the curing process, resulting in poor curing. 3. Insufficient paint leveling time leads to insufficient leveling of the paint film; 4. Insufficient cooling time after curing can cause overheating or insufficient fixation of the workpiece (or lower part) during the coating process.

3、涂装设备选择不当由于不同产品的不同要求,设备选择也不同,各种涂装设备各有利弊。如果无法向用户解释设计,客户会发现制造完成后涂层生产线不满意。例如,粉末喷涂干燥隧道采用空气幕隔热,有清洁要求的工件不安装净化设备。这种错误是涂装设备工艺布局中最常见的错误。

3. Improper selection of painting equipment is due to the different requirements of different products, and the selection of equipment is also different. Each painting equipment has its own advantages and disadvantages. If the design cannot be explained to the user, the customer will find that the coating production line is not satisfied after manufacturing is completed. For example, powder spray drying tunnels use air curtains for insulation, and workpieces with cleaning requirements do not have purification equipment installed. This type of error is the most common mistake in the layout of painting equipment processes.

4、未考虑涂装设备节能问题

4. Not considering the energy-saving issue of painting equipment

目前,这种能源的价格变化相对较快。然而,如果在设计中不考虑这些问题,用户的生产成本将会更高,一些用户将不得不在短时间内重建和购买设备。这不是顾客想要的。涂装设备工艺布局设计的质量对涂装生产线的使用至关重要。如果涂装设备的工艺布局不当,即使每一件设备都制造得很好,整个涂装生产线也不容易使用。因此,在设计时,我们必须避免上述常见错误,从而造成不必要的损失!

At present, the price of this energy source changes relatively quickly. However, if these issues are not considered in the design, the production cost for users will be higher, and some users will have to rebuild and purchase equipment in a short period of time. This is not what the customer wants. The quality of process layout design for painting equipment is crucial for the use of painting production lines. If the process layout of the painting equipment is improper, even if each piece of equipment is manufactured well, the entire painting production line is not easy to use. Therefore, in design, we must avoid the common errors mentioned above, which can cause unnecessary losses!

本文由 工业涂装流水线 友情奉献.更多有关的知识请点击 http://www.sdcjtz.com/ 真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the industrial painting assembly line For more related knowledge, please click http://www.sdcjtz.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:工业涂装流水线的七大组成部分

下一篇:工业涂装生产线;美式涂装工艺有哪些

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号