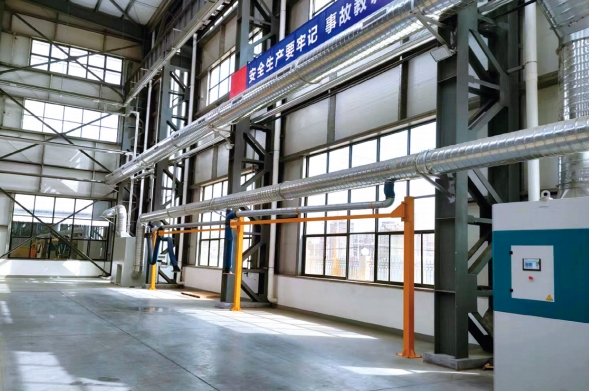

车间整体除尘设备:好好维护才能延长寿命

车间整体除尘设备的正确维护对于保持设备的良好运行状态、延长使用寿命以及确保生产环境的清洁至关重要。以下是一些关键的维护步骤和措施:

The correct maintenance of the overall dust removal equipment in the workshop is crucial for maintaining the good operating condition of the equipment, extending its service life, and ensuring the cleanliness of the production environment. Here are some key maintenance steps and measures:

1. 定期检查:

1. Regular inspection:

检查除尘设备的滤袋是否需要更换,根据压差计的读数判断滤袋是否堵塞。

Check if the filter bag of the dust removal equipment needs to be replaced, and determine if the filter bag is clogged based on the reading of the differential pressure gauge.

检查电磁脉冲阀是否正常工作,无故障。

Check if the electromagnetic pulse valve is working properly and there are no faults.

检查气源处理器中的杂质和积水,定期排放。

Check for impurities and accumulated water in the air source processor and discharge regularly.

2. 清洁工作:

2. Cleaning work:

保持设备内外的清洁,特别是风机、电机等关键部件。

Keep the inside and outside of the equipment clean, especially key components such as fans and motors.

清除设备周围的灰尘和杂物,保持通风良好。

Remove dust and debris around the equipment and maintain good ventilation.

3. 润滑和加油:

3. Lubrication and refueling:

定期给设备的传动装置加油,并注意防尘。

Regularly lubricate the transmission device of the equipment and pay attention to dust prevention.

检查油水分离器,定期排污。

Check the oil-water separator and regularly discharge water.

4. 紧固件检查:

4. Inspection of fasteners:

检查设备的紧固件是否松动,及时紧固。

Check if the fasteners of the equipment are loose and tighten them in a timely manner.

5. 电源线维护:

5. Power cord maintenance:

检查电源线是否老化,防止短路或漏电。

Check if the power cord is aging to prevent short circuits or leakage.

6. 运行监控:

6. Operation monitoring:

监控设备的运行状态,如有异常及时处理。

Monitor the operating status of the monitoring equipment and promptly handle any abnormalities.

7. 停机维护:

7. Shutdown maintenance:

设备停机时,应清灰,避免潮气和粉尘黏糊在袋子上造成设备故障。

When the equipment is shut down, the dust should be cleaned to avoid moisture and dust sticking to the bag and causing equipment failure.

8. 专业培训:

8. Professional training:

对车间管理人员和操作人员进行定期培训,提高维护技能。

Regularly train workshop managers and operators to improve maintenance skills.

通过上述措施,可以确保车间整体除尘设备的长期稳定运行,提高除尘效率,同时也能延长设备的使用寿命,降低维护成本。

Through the above measures, the long-term stable operation of the overall dust removal equipment in the workshop can be ensured, the dust removal efficiency can be improved, and the service life of the equipment can also be extended, reducing maintenance costs.

本文由车间整体除尘设备提供帮助,更多的相关内容请点击:http://www.sdcjtz.com希望本文能够为您带来帮助,感谢您的阅读!

This article is assisted by the overall dust removal equipment in the workshop. For more related content, please click: http://www.sdcjtz.com I hope this article can be helpful to you. Thank you for reading!

上一篇:

下一篇:环保伸缩喷漆房在设计上要注意什么?

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号