工业涂装流水线作业流程

前处理工序:在正式开启涂装作业之前,对工件进行全面、细致的前处理是必不可少的重要环节。首先进行除油操作,利用专门配置的除油剂,将工件表面的油污彻底溶解并清除干净,为后续工序创造良好的基础条件。紧接着进行除锈工序,运用物理打磨或化学腐蚀等方法,将工件表面的锈迹彻底去除,还原工件原本的金属光泽与质地。随后进入磷化工序,通过特定的化学反应,在工件表面生成一层均匀且略带粗糙感的灰色磷化膜。这层磷化膜不仅具有卓越的防锈性能,能够有效抵御外界环境对工件的侵蚀,还能显著增强后续喷塑层与工件表面的附着力,为提升涂装质量奠定坚实基础。最后进行钝化处理,进一步优化工件表面的化学性质,提高其耐腐蚀性与稳定性,使工件以最佳状态进入后续的涂装工序。

Pre treatment process: Before officially starting the painting operation, comprehensive and meticulous pre-treatment of the workpiece is an essential and important step. Firstly, perform oil removal operation by using specially configured oil removal agents to thoroughly dissolve and clean the oil stains on the surface of the workpiece, creating a good foundation for subsequent processes. Next, the rust removal process is carried out, using physical polishing or chemical corrosion methods to completely remove the rust on the surface of the workpiece, restoring the original metallic luster and texture of the workpiece. Subsequently, it enters the phosphating process, where a specific chemical reaction generates a uniform and slightly rough gray phosphating film on the surface of the workpiece. This phosphating film not only has excellent anti rust performance, which can effectively resist the erosion of the workpiece by the external environment, but also significantly enhance the adhesion between the subsequent spray coating layer and the workpiece surface, laying a solid foundation for improving the coating quality. Finally, passivation treatment is carried out to further optimize the chemical properties of the workpiece surface, improve its corrosion resistance and stability, and enable the workpiece to enter the subsequent coating process in the optimal state.

预热与底漆喷涂:经过前处理的工件随即进入预热阶段,通过精准控制加热温度,使工件表面温度适度升高。这一预热过程能够有效提升底漆与工件表面的亲和性,为底漆的牢固附着创造有利条件。预热完成后,便借助喷粉系统或喷漆设备对工件进行底漆喷涂作业。底漆作为整个涂层体系的基础,其主要作用在于增强工件与面漆之间的附着力,同时为工件提供初步的防锈和防护功能,为后续的面漆涂装打造稳固的根基。

Preheating and Primer Spraying: After pre-treatment, the workpiece immediately enters the preheating stage, and the surface temperature of the workpiece is moderately increased by precisely controlling the heating temperature. This preheating process can effectively enhance the affinity between the primer and the workpiece surface, creating favorable conditions for the firm adhesion of the primer. After preheating is completed, the workpiece is sprayed with primer using a powder spraying system or spray painting equipment. As the foundation of the entire coating system, the main function of primer is to enhance the adhesion between the workpiece and the topcoat, while providing preliminary rust prevention and protection functions for the workpiece, creating a stable foundation for subsequent topcoat coating.

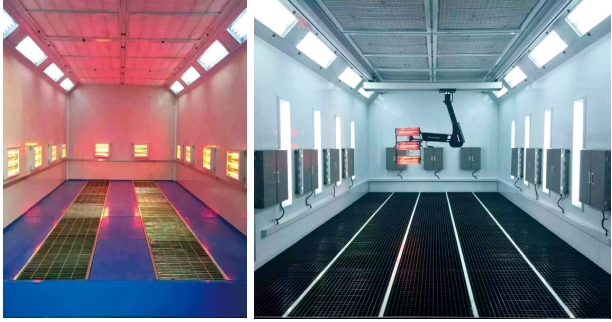

烘烤与表面喷漆:完成底漆喷涂后,工件进入烘烤环节。在特定的高温环境下,底漆中的溶剂迅速挥发,涂层中的成分发生交联反应,逐渐固化成型。烘烤工序不仅能够使底漆与工件表面紧密结合,还能提升底漆的硬度与耐磨性。烘烤完成后,进入表面喷漆工序。根据产品的设计要求与市场定位,精心挑选合适的液态涂料,运用喷漆设备对工件进行精细喷涂,以实现所需的色彩效果、光泽度以及表面纹理,赋予产品独特的外观魅力。

Baking and surface painting: After completing the primer spraying, the workpiece enters the baking process. In a specific high-temperature environment, the solvent in the primer rapidly evaporates, and the components in the coating undergo cross-linking reactions, gradually solidifying and forming. The baking process can not only tightly bond the primer with the surface of the workpiece, but also improve the hardness and wear resistance of the primer. After baking, enter the surface painting process. According to the design requirements and market positioning of the product, carefully select suitable liquid coatings, and use spray painting equipment to finely spray the workpiece to achieve the desired color effect, glossiness, and surface texture, giving the product a unique appearance charm.

高温固化:最后,经过表面喷漆的工件进入高温固化烘道。在高温的作用下,涂层中的各类成分发生更为深入、彻底的交联反应,形成一层结构紧密、性能卓越的保护膜。高温固化过程能够显著提升涂层的硬度、耐磨性、耐腐蚀性以及耐候性等关键性能指标,确保涂装效果具备长期的稳定性与可靠性,使产品能够在各种复杂的使用环境下始终保持出色的外观与防护性能。

High temperature curing: Finally, the surface painted workpiece enters the high-temperature curing oven. Under the action of high temperature, various components in the coating undergo deeper and more thorough cross-linking reactions, forming a tightly structured and high-performance protective film. The high-temperature curing process can significantly improve key performance indicators such as hardness, wear resistance, corrosion resistance, and weather resistance of the coating, ensuring long-term stability and reliability of the coating effect, and enabling the product to maintain excellent appearance and protective performance in various complex use environments.

本文由工业涂装流水线友情奉献.更多有关的知识请点击:http://www.sdcjtz.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号