工业涂装流水线有哪些工艺流程?

工业涂装流水线的工艺流程主要包括加热固化、喷粉涂装以及前处理三个环节。

The process flow of industrial coating assembly line mainly includes three steps: heating and curing, powder coating, and pre-treatment.

工业涂装流水线在前处理阶段,工件需经过表面处理以去除油污和锈蚀,这通常涉及手动简易或自动前处理,后者又分为自动喷淋和自动浸喷两种方式。在此过程中,会使用到多种药液,如除油剂、除锈剂、表调剂和磷化剂等。

In the pre-treatment stage of industrial painting assembly lines, workpieces need to undergo surface treatment to remove oil stains and rust, which usually involves manual or automatic pre-treatment, the latter of which is divided into two methods: automatic spraying and automatic immersion spraying. During this process, various chemical solutions will be used, such as degreasers, rust removers, surface conditioners, and phosphating agents.

安全措施在前处理工段至关重要,包括制定强酸强碱的管理制度、提供必要的保护着装,以及配置安全可靠的搬运、盛装和配置器具。同时,还需制定应对突发事故的紧急处理措施。

Safety measures are crucial in the pre-processing section, including establishing a management system for strong acids and alkalis, providing necessary protective clothing, and configuring safe and reliable handling, packaging, and equipment. At the same time, emergency response measures for sudden accidents need to be formulated.

此外,环保措施也不容忽视,需配置抽气排气、排液和三废处理装置以处理可能产生的废气、废液等。

In addition, environmental protection measures cannot be ignored, and it is necessary to install exhaust, liquid discharge, and three waste treatment devices to treat possible waste gases, liquids, etc.

经过前处理的工件,其质量会受到前处理液及涂装流水线工艺流程的影响。为防止短时间内再次生锈,一般会在前处理后的几道工序中进行磷化或钝化处理。在喷粉前,还需对已磷化的工件进行干燥以去除表面水分。

The quality of workpieces that have undergone pre-treatment will be affected by the pre-treatment solution and the coating assembly line process flow. To prevent rusting again in a short period of time, phosphating or passivation treatment is usually carried out in several processes after pre-treatment. Before powder coating, the phosphated workpiece needs to be dried to remove surface moisture.

在喷粉涂装阶段,少量工件可手动喷粉,而大量工件则通常采用自动或手动喷粉装置。关键是要确保所喷工件着粉均匀、厚度一致,避免薄喷、漏喷和擦落等缺陷。

During the powder coating stage, a small number of workpieces can be manually powder coated, while a large number of workpieces usually use automatic or manual powder coating devices. The key is to ensure that the sprayed workpiece has uniform powder coating and consistent thickness, avoiding defects such as thin spraying, missed spraying, and scraping off.

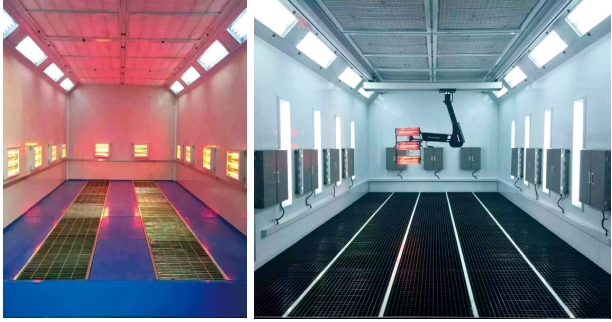

最后是工业涂装流水线的固化工序,此环节需注意防止粉末碰落和擦粉现象,并严格控制烘烤工艺及温度、时间,以防止色差和固化不足的问题。对于大量自动输送的工件,同样需要仔细检查是否漏喷、喷薄或局部擦粉,确保合格工件进入烘道。

Finally, the curing process of the industrial coating assembly line requires attention to preventing powder from falling off and rubbing, and strictly controlling the baking process, temperature, and time to prevent color difference and insufficient curing. For a large number of automatically transported workpieces, it is also necessary to carefully check for any missed spraying, thinning, or localized powder coating to ensure that qualified workpieces enter the drying oven.

涂装,即将保护层或装饰层覆盖于非金属和金属表面,旨在增强其耐用性和美观度。随着科技的不断进步,涂装流水线已从手工模式逐渐演变为高度自动化的生产线,其应用领域亦日益广泛。

Painting, which involves covering non-metallic and metallic surfaces with a protective or decorative layer to enhance their durability and aesthetic appeal. With the continuous advancement of technology, the painting assembly line has gradually evolved from manual mode to highly automated production line, and its application fields are becoming increasingly widespread.

本文由工业涂装流水线友情奉献.更多有关的知识请点击:http://www.sdcjtz.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from the industrial painting assembly line For more information, please click: http://www.sdcjtz.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

上一篇:VOCs废气该怎么处理

下一篇:使用自动式抛丸机要注意什么?

鲁公网安备 37142502000144号

鲁公网安备 37142502000144号